Views: 10

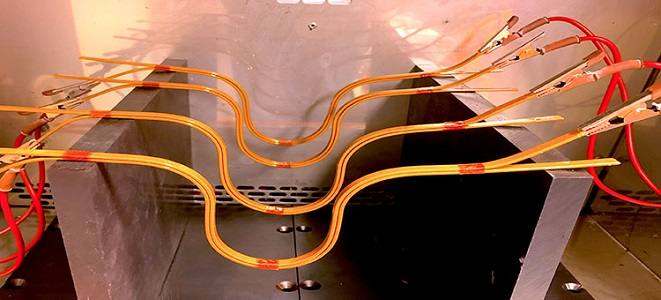

– The insulation materials were tested in the lab facilities of electric power engineering at Chalmers.

Courtesy Chalmers: A new insulation material for conductors increases the average lifetime of motor insulation in electric car by about eight times. The material consists of a thin polyimide film, that is resistant to chemical degradation from electrons.

In a collaboration project with ABB Sweden and DuPont, researchers at Chalmers University of Technology have evaluated new materials for motor insulation exposed for modern power electronics inverters, especially for electromobility applications.

The study evaluated the impact on the insulation material of increased electrical stresses caused by high switching frequency converters with a faster rise of voltage with respect to time on the conductor insulation materials used in today’s advanced traction motors. These converters are usually silicon carbide-based and can be found in modern electric car. In the tests the conductor insulation was also exposed to high temperatures (150 to 180°C) and high voltages (3.0 and 3.5 kV).

New material provides an eight-fold improvement

“We concluded that Kapton ECRC polyimide films may be considered as proper candidates for traction motors supplied by high-switching frequency converters designed and produced for the electrification market,” says Shafigh Nategh, research project leader at ABB and adjunct associate professor at the department of Electrical Engineering at Chalmers.

“The comparison between non-corona resistant Kapton FN and the 25 percent thinner corona resistant Kapton ECRC materials showed that Kapton ECRC film increased the average life-time of the insulation by about eight times.”

“The research findings help DuPont better understand the impact of increased switching frequency from inverters on a new generation of corona-resistant Kapton polyimide film wire insulation,” says Shawn Filliben, technical service senior consultant for DuPont Kapton films.

“This new technology will enable designers to have higher performing thin insulation to compete with historical enamel solutions. A thinner insulation material will also provide an additional degree of design freedom for those looking to create smaller, more reliable motors.”

“Chalmers has a strong background in electric power engineering, and we are involved in exploring new technologies for electromobility applications together with several well-known industrial partners,” says

, professor and head of the unit Electrical Machines and Power Electronics at Chalmers. ”This is an excellent show-case project for collaboration between industry and academia.”

Three complementary roles

With strong background in motor manufacturing, ABB formulated the new challenges in electrical machines for future vehicles and verified the new solutions against the targeted applications. DuPont, one of the world’s largest insulation material producers, provided the newest materials to deal with challenges.

Chalmers, with strong electronics hardware competence and good lab facilities, developed advanced testing set-up and conducted time-consuming sample tests.

“We are very proud that Chalmers could contribute to this evaluation of the break-through insulation technology with world-leading companies. To become a preferable collaboration partner worldwide is a goal that we strive for”, says Yujing Liu.

More about the project

The Chalmers team, led by Professor Yujing Liu, has collaborated closely with ABB and DuPont in the project to evaluate the new materials. Researcher Dr. Xiaoliang Huang and PhD student Bowen Jiang designed and built the experimental setup and supervised testing. Master’s thesis student Numair Alhallak simulated test system and monitored all the tests during several months.

The project was conducted in 2019 and 2020, and was jointly funded by the Swedish Energy Agency and ABB.

The final findings will be published in two scientific papers at the IEEE Workshop on Electrical Machine Design, Control and Diagnostics (WEMDCD) on 8–9 April 2021, in Modena, Italy. Electric car

For more information, contact: Yujing Liu, professor of electric power engineering at the department of Electrical Engineering, Chalmers University of Technology, yujing.liu@chalmers.se

Other sources: DUPONT

Related article: Sustainable fuels for heavy trucks