Views: 9

– Researchers at ETH Zurich have developed a technique for making length micrometer machines, interconnecting various materials in a complex way. These micro robots will one day revolutionize the medical field.

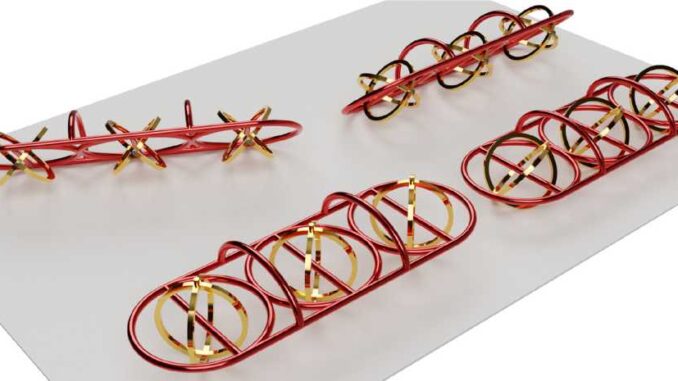

Courtesy ETH: Robotic micromachines so small that they can maneuver through our blood vessels and deliver drugs to certain parts of the body – researchers have been pursuing this goal for years. Now, scientists at ETH Zurich have managed for the first time to build these “micromachines”, metal and plastic robots, in which these two materials are interconnected like links in a chain. This is possible thanks to a new manufacturing technique that they have developed.

“Metals and polymers have different properties and both materials offer certain advantages in the construction of micro-machines. Our goal was to take advantage of all these properties simultaneously, combining the two ”, explains Carlos Alcântara, a former doctoral student in the Salvador Pané group at the Robotics and Intelligent Systems Institute and one of the main authors of the article.

As a rule, robotic micromachines are powered from outside the body using magnetic fields, which means they must have magnetic metal parts installed. Polymers, in contrast, have the advantage that they can be used to build soft, flexible components, as well as parts that dissolve within the body. If the drug is embedded in this type of soluble polymer, it is possible to selectively deliver active substances to certain points of the body.

High-tech production method

The basis of the new manufacturing method is the expertise of ETH Professor Salvador Pané. For years, he worked with a high-precision 3D printing technique that produces complex objects at the micrometer level, a technique known as 3D lithography. ETH scientists applied this method to produce a kind of mold or template for their micro-machines. These models have narrow grooves that act as a “negative” and can be filled with the chosen materials.

Using electrochemical deposition, scientists fill some of the grooves with metal and others with polymers before dissolving the mold with solvents. “Our interdisciplinary group consists of electrical engineers, mechanical engineers, chemists and material scientists who work together. That was the key to the development of this method ”, says Fabian Landers, a doctoral student in the Pané group. He is the other main author of the article, which was published in the journal Nature Communications.

Vehicle with tiny magnetic wheels

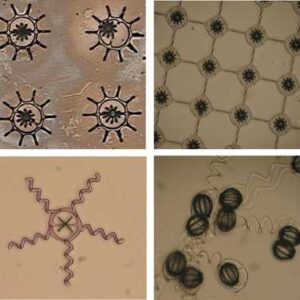

As a proof of principle for making robotic micromachines, using interconnected materials, the ETH scientists created several tiny vehicles with plastic chassis and magnetic metal wheels driven by a rotating magnetic field. Some of the vehicles can be propelled on a glass surface, while others – depending on the polymer used – can float on a liquid or on a liquid surface.

Scientists now plan to refine their two-component robotic micromachines and experiment with other materials. In addition, they will try to create more complex shapes and machines, including some that can fold and unfold.

In addition to serving as “rafts” that deliver active substances, future applications for micromachines include treating aneurysms (bulges in blood vessels) or performing other surgical procedures.

Another objective of the research is to make stents (support of vessels in the form of a tube) that unfold and can be positioned in a specific location of the body through magnetic fields.

Reference: Alcântara CCJ, Landers FC, Kim S, De Marco C, Ahmed D, Nelson BJ, Pané S: Mechanically Interlocked 3D Multi-Material Micromachines, Nature Communications, November 24 2020, doi: 10.1038 / s41467-020-19725-6

Related article: Laser jolts microscopic robots into motion