Views: 8

– The new approach, developed by chemical engineers at MIT, can help create more efficient consumer products, including medicines, cosmetics and food.

Courtesy MIT by Elizabeth A. Thomson: In a job that can have a big impact on a number of industries – from pharmaceuticals to cosmetics and even food – MIT engineers have developed a new platform for the controlled delivery of certain drugs, nutrients and other important substances for human cells.

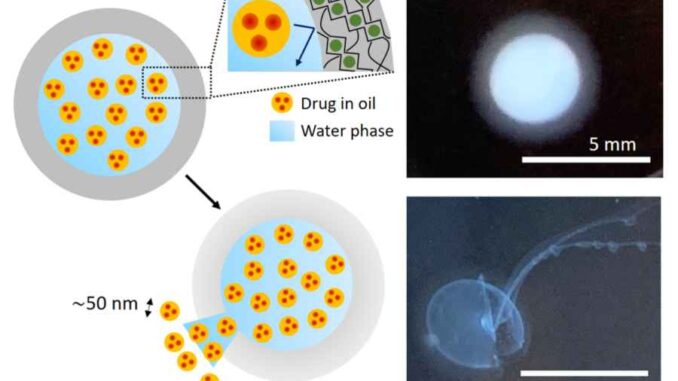

The researchers believe that their simple approach, which creates small capsules containing thousands of nanometric droplets loaded with a drug or other active ingredient, will be easy to transition from the laboratory to the industry.

The active ingredients in many consumer products intended for use on the human body do not easily dissolve in water. As a result, they are difficult to be absorbed by the body and it is difficult to control their delivery to cells.

In the pharmaceutical industry alone, “40 percent of drugs currently marketed and 90 percent of drugs in development are hydrophobic, where [their] low water solubility greatly limits their bioavailability and absorption efficiency,” writes the MIT team in a article about the work in the August 28 edition of the Advanced Science magazine.

Nanoemulsions to the rescue

These drugs and other hydrophobic active ingredients, however, dissolve in the oil. Hence the growing interest in nanoemulsions, the nanoscale equivalent of an oil and vinegar salad dressing that consists of tiny oil droplets dispersed in water. Dissolved in each drop of oil is the active ingredient of interest.

Among other advantages, droplets loaded with ingredient can easily pass through cell walls. Each drop is so small that between 1,000 to 5,000 could fit the width of a human hair. (Their macro-scale counterparts are too large to be transmitted.) Once the droplets are inside the cell, their payload can have an effect. The droplets are also exceptionally stable, resulting in a long shelf life, and can contain a large amount of active ingredient for their size.

But there is a problem: how do you encapsulate a nanoemulsion in a dosage form like a pill? The technologies to do this are still incipient.

In one of the most promising approaches, the nanoemulsion is encapsulated in a 3D network of a polymer gel to form small granules. Today, however, when ingested, these granules release their payload – oil droplets loaded with ingredients – all at once. There is no control over the process.

The MIT team solved this by adding a shell, or capsule, around large individual drops of nanoemulsion, each containing thousands of drops of nano oil. This wrapper not only protects nano droplets from within the body’s harmful physiological conditions, but can also be used to mask the often unpleasant taste of the active ingredients they contain.

The result is a “pill” about 5 millimeters in diameter with a biodegradable shell that in turn can be “adjusted” to release its content at specific times. This is done by changing the thickness of the shell. To date, they have successfully tested the system with ibuprofen and vitamin E.

“Our new delivery platform can be applied to a wide range of nanoemulsions, which contain active ingredients ranging from medicines to nutraceuticals and sunscreens. Having this new control over how you deliver them opens up many new avenues in terms of future applications, ”says Patrick Doyle, Robert T. Haslam Professor of Chemical Engineering and senior author of the article.

His colleagues at work are Liang-Hsun Chen, a graduate student in chemical engineering and first author of the article, and Li-Chiun Cheng SM ’18, PhD ’20, who received his PhD in chemical engineering earlier this year and is now at LiquiGlide.

Many advantages

The MIT platform has several advantages, in addition to its simplicity and scalability for the industry. For example, the shell itself “is derived from the cell walls of brown algae, so it is very natural and biocompatible with the human body,” says Chen.

In addition, the process for making the nanoemulsion containing its payload is economical because the simple agitation involved requires little energy. The process is also “very smooth, which protects the [active] molecule of interest, like a drug,” says Doyle. “Harder techniques can damage them.”

The team also demonstrated the ability to transform the liquid nanoemulsion inside each shell into a solid core, which could allow for a variety of other applications. They did this by adding a material that, when activated by ultraviolet light, cross-links the oil nanoparticles.

For Chen, the most exciting part of the job was preparing the capsules and then “seeing them burst to release their content at the times I designed them for”

Doyle notes that from a pedagogical point of view, the work “combined all the core elements of chemical engineering, from fluid dynamics to reaction engineering and mass transfer. And for me it is very cool to have them all in one project. “

This work was funded by the Singapore National Research Foundation, the US National Science Foundation and the Think Global Education Trust – Taiwan.

Related article: On the road to safe nanomedicine