Views: 143

Empa and G-ray team up to develop a world’s first in metal 3D printing. G-ray, a Neuchatel-based start up, will provide real-time quality control during the manufacturing process.

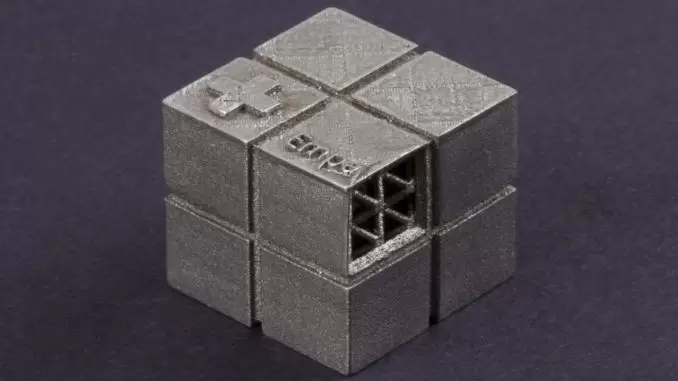

Courtesy EMPA by Rainer Klose : Empa’s novel 3D printing system will be based on Electron Beam Melting (EBM) – a printing method, which promises high melting capacity and high productivity. In EBM the electron beam is managed by electromagnetic coils providing very fast and accurate beam control that allows several melt pools to be maintained simultaneously. The process takes place in vacuum and at high temperature.

In order to monitor the manufacturing process in real time, Empa will incorporate G-ray’s X-ray detectors into the prototype 3D printer, which is currently developed at Empa’s Laboratory for Advanced Materials Processing led by Patrik Hoffmann in Thun.

G-ray’s latenium™ X-ray detectors will provide the central core element to support the real-time monitoring of a revolutionary additive manufacturing printer under development at Empa.

“Empa’s novel 3-D printing system will allow for real-time monitoring of the production process”, says Patrick Hoffmann, Head of laboratory for Advanced Materials Processing.

G-ray Nanobonding and CSEM have achieved a major milestone in packaging the latenium™ technology to deliver disruptive industrial non-destructive testing solutions: the latenium™ Evaluation Kit. Centered on photon-counting X-ray imaging, these unique solutions are set to improve the quality of the images obtained to significantly improve industrial products such as aeronautics engines and 3-D printed products, among others.

G-ray, is currently developing ultra-high performance detectors dedicated to industrial non-destructive testing solutions. “These detectors are being developed in partnership with CSEM (CH) and BRUCO electronics (NL), based on G-ray’s revolutionary latenium™ technology. The latenium™ Evaluation Kits are available for qualification purposes as of Q1-2019 from G-ray. Additive manufacturing represents a huge potential for our latenium™ detectors”, says Philippe Le Corre, CEO of G-ray.

Researchers at Empa, the Swiss Federal Laboratories for Materials Science and Technology, are developing novel materials to be used in industrial processes in the future as well as the respective production technologies. Empa’s Laboratory for Advanced Materials Processing is currently carrying out research on real-time monitoring and data analysis for future closed loop process control of additive manufacturing printing processes. “Adding rapid, high-resolution in-situ X-ray detection will be an extraordinary additional tool for pursuing our work”, says Patrik Hoffmann, the head of the laboratory. The G-ray detectors might become an essential real-time process detector installed in additive manufacturing machines of the future, especially for electron beam 3-D printers and welding systems.

“The outcome of this project has huge potential in multiple industries”, says Philippe Laufer, CEO, CATIA, Dassault Systèmes. “Our customers are adopting what we call ‘V+R’ – virtual plus real – additive manufacturing processes at the speed of light. Non-destructive quality control, and its feedback to the virtual design, engineering and process planning stages are eagerly awaited, especially by the aerospace and defense, and energy and materials industries.”

Related article: Printing- SEAM makes it faster and cheaper

Leave a Reply