Views: 14

– Development of cell-based 3D fiber structure for artificial muscle regeneration

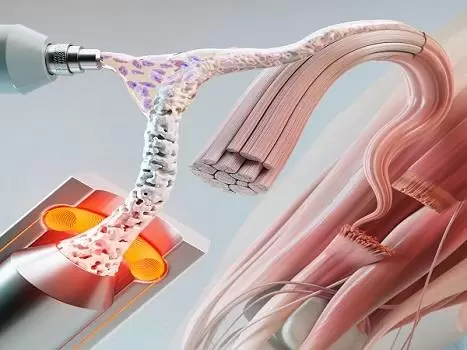

Minapim by Hernan Valenzuela: The research team of Professor Seong-Jun Park, from the Department of Bio and Brain Engineering at Yonsei University, announced that it has developed a customized 3D structure, an artificial muscle based on cells, to regenerate muscles, blood vessels and nerve tissues using fiber optic fabrication methods in conjunction with Yonsei University and MIT research teams.

Muscle loss that occurs after trauma and tumor resection is a major cause of long-term restriction of patient movement. Currently, a transplant-based method of surgery is being performed for treatment, but this has a problem that not only can cause problems at the site provided by the tissue, but also the effective regeneration capacity and muscle functionality do not appear sufficiently in the transplanted muscles. .

As an alternative to this, research is being conducted to induce skeletal muscle regeneration through direct cell transplantation to the damaged area, but current technology is difficult to apply in real clinical practice due to the lack of functionality and survival rate in long-term cells.

To solve the problem, the research team used direct reprogramming of fibroblasts to convert them into induced myogenic progenitor cells (iMPCs).

In addition, as it is necessary to provide an ideal mechanical / biochemical microenvironment for effective cell differentiation and growth, the research team solved this by providing a hybrid 3D structure through a combination of an appropriate artificial / natural polymer.

The first material used to manufacture the structure is a PCL polymer – polycarpolactone, with excellent biocompatibility and resistance.

The research team has successfully fabricated a fiber-based 3D PCL structure using a thermal stretching process (TDP) used primarily to manufacture optical fibers and a salt leaching method to form a porous structure.

This process has the advantage of allowing the mass production of the structure while being able to freely control the size, strength and porosity of the structure. The second material is an extracellular matrix (ECM) made using a decellularization process, and the researchers were able to provide an ideal differentiation environment for transplanted cells through an appropriate combination of the two materials.

As a result, the research team confirmed that not only were the differentiation and formation of muscle cells promoted in in vitro and in vivo models, but also the distribution of peripheral nerves and blood vessels in addition to increased muscles.

In addition, in the volumetric muscle loss model for mice, the research team confirmed that when the structure developed and the cells were transplanted together, the capacity of the regenerated muscle increased dramatically compared to when only the cells were transplanted.

Professor Seong-Jun Park, who led the research, said: “This research is significant because we have developed a new method that can mass-produce custom 3D structures for the regeneration of various tissues in addition to muscles in the future.

Since then, this technology has developed a variety of biomaterials and stem cells. When combined with technology, we hope to create great synergy in the areas of tissue engineering and the development of artificial muscles. ”

The results of the study were published in the international journal Advanced Materials on February 19, 2021. (Article name: functional regeneration of skeletal muscle with thermally drawn porous fibers and muscle progenitors reprogrammed for volumetric muscle injury)

Source: KAIST

Related article: A new bone can be formed into a gel?