Views: 8

– The study shows how mixing multiple molecules – up to eight at a time – can result in a material that performs as well as the best currently known glass formers.

Courtesy Chalmers University: Researchers at Chalmers University of Technology, Sweden, have succeeded in creating a new type of super durable and stable glass with potential applications ranging from medicines, advanced digital screens, and solar cell technology. A glass, also known as an ‘amorphous solid’, is a material that does not have a long-range ordered structure – it does not form a crystal. Crystalline materials on the other hand are those with a highly ordered and repeating pattern. The fact that a glass does not contain crystals is what makes it useful.

The materials that we commonly call ‘glass’ in every day life are mostly silicon dioxide-based, but glass can be formed from many different materials. Researchers are therefore always interested in finding new ways to encourage different materials to form this amorphous state, which can potentially lead to the development of new types of glass with improved properties and new applications. The new study, recently published in the scientific journal Science Advances, represents an important step forward in that search.

“Now, we have suddenly opened up the potential to create new and better glassy materials, by simply mixing many different molecules. Those working with organic molecules know that using mixtures of two or three different molecules can help to form a glass, but few might have expected that the addition of more molecules, and this many, would achieve such superior results,” says Professor Christian Müller at the Department of Chemistry and Chemical Engineering at Chalmers University who led the research team behind the study.

Best result for any glass forming material

A glass is formed when a liquid is cooled down without undergoing crystallisation, a process called vitrification. The use of mixtures of two or three molecules to encourage glass formation is a well-established concept. However, the impact of mixing a multitude of molecules on the ability to form a glass has received little attention.

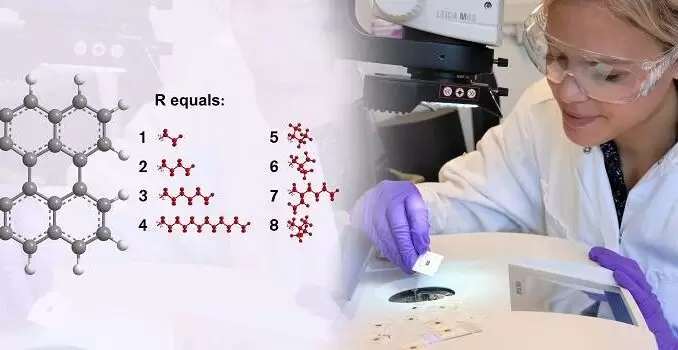

The researchers experimented with a mixture of up to eight different perylene molecules which, individually, have a high fragility – a property related to how easy it is for a material to form a glass. But mixing the many molecules together resulted in a substantial decrease in fragility, and a very strong glass former with ultralow fragility was formed.

“The fragility of the glass we created in the study is very low, representing the best glass-forming ability that has been measured not only for any organic material but also polymers and inorganic materials such as bulk metallic glasses. The results are even superior to the glass forming ability of ordinary window glass, one of the best glass formers that we know of,” says Sandra Hultmark, doctoral student at the Department of Chemistry and Chemical Engineering and lead author of the study.

Extending product life and saving resources

Important applications for more stable glass organic are display technologies such as OLED screens and renewable energy technologies such as organic solar cells. “OLEDs are constructed with glassy layers of light-emitting organic molecules. If these were more stable glasses, it may improve the durability of an OLED and ultimately the display,” Sandra Hultmark explains.

Another application that may benefit from more stable glass are pharmaceuticals. Amorphous drugs dissolve more quickly, which aids rapid uptake of the active ingredient upon ingestion. Hence, many pharmaceuticals make use of glass-forming drug formations. For pharmaceuticals it is vital that the glassy material does not crystallise over time. The more stable the glassy drug, the longer the shelf life of the medicine.

“With more stable glass or new glass forming materials, we could extend the lifespan of a large number of products, offering savings in terms of both resources and economy,” says Christian Müller.

More about the research

- The scientific article “Vitrification of octonary perylene mixtures with ultralow fragility” has been published in the scientific journal Science Advances and is written by Sandra Hultmark, Alex Cravcenco, Khuschbu Khushwaha, Suman Mallick, Paul Erhardt, Karl Börjesson and Christian Müller. The researchers are active at Chalmers University of Technology and the University of Gothenburg.

- The researchers chose to work with a series of small, conjugated molecules comprising a perylene core with different pendant alkyl groups at one of the bay positions. All eight perylene derivatives readily crystallise when cast from solution and show a fragility of more than 70.

- Mixing of eight perylene derivatives resulted in a material that displays a fragility of only 13, which is a record low value for any glass forming material studied to date, including polymers and inorganic materials such as bulk metallic glasses and silicon dioxide.

- The research project was funded by the Swedish Research Council, the European Research Council, as well as the Knut and Alice Wallenberg Foundation through project: Mastering Morphology for Solution-born Electronics.

For more information, contact: Christian Müller, Professor at the Department of Chemistry and Chemical Engineering, Chalmers University of Technology, +46 31-77227 90 christian.muller@chalmers.se

Sandra Hultmark, doctoral student at the Department of Chemistry and Chemical Engineering, Chalmers University of Technology sanhul@chalmers.se

Related article: China set to become largest market for OLED televisions

Leave a Reply